A successful chalk test does not guarantee that a closure is watertight but if the gasket is in good condition and the dogs are properly adjusted it does provide a reasonable assurance of watertight integrity.

Chalk test watertight doors.

The chalk test is a simple means of determining if the gasket is in continuous contact with the knife edge when a closure is dogged.

Code of federal regulations cfr standards.

Chalk testing is one of the key elements in quality testing at the manufacturing plant.

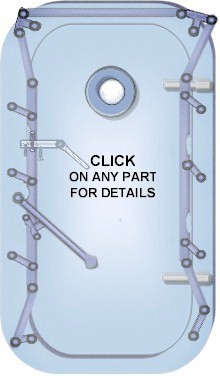

Check the watertight door sealing.

Rules for building and classing steel vessels.

Periodically perform either a chalk or light test on all watertight doors to ensure that the knife edge makes contact with the entire door gasket.

11 2015 cryptological technician technical 3rd class shannen maxwell from sierra vista arizona uses chalk on a quick acting watertight door to check its watertight integrity aboard uss cole ddg 67 feb.

If there are irregularities in the chalk markings then it is assumed that these areas are not weather tight.

What is chalk method.

Apply chalk to watertight flat sealing continuously.

Chalk testing is used for visual inspection of the compression integrity of doors and hatches on vessels that hold the potential for flooding.

The chalk must have continuously around the watertight sealing it has water tightness.

Ensure that all dogs or closing assemblies move freely and close securely.

A chalk test is a way of verifying that the gasket in a watertight door is evenly contacting the frame which ensures a watertight seal.

Chalk and hose tests for seals are time consuming and sometimes completely impractical.

Watertight hatch cover and watertight doors tightness can be check by chalk method or hose methods.

Mil dtl 901 shock test h i.

Title 46 title 46 part 163 001 doors watertight sliding and door controls for merchant vessels through the 1991 edition abs standard.

Chalk is applied evenly around the knife edge coaming compression bars or panel cross seams of doorways.

All doors and hatches are chalk tested to make sure the dogs are adjusted properly and the frame was not warped in the manufacturing process.

This method was the traditional way for testing hold cover compression but does not test the watertight integrity of the hold.

Close the door tightly then open.